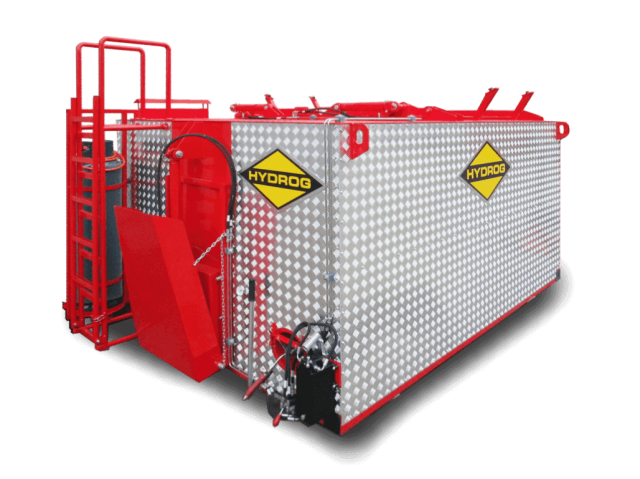

Asphalt hot boxes TR-H (with auger discharge)

INTENDED USE OF ASPHALT HOT BOX

- Pothole preparation with a hammer or a saw driven by a built-in hydraulic power unit

- Sprinkling of the pothole with a bitumen emulsion with a built-in sprayer

- Dosing of a hot bituminous mass with a screw feeder and a chute on turntable

HYDROG ASPHALT-THERMO-COINTAINER - BASIC FEATURES

- Screw feeder with an adjustable speed and overload protection

- Built-in air compressor for sprayer lance cleaning

- The largest top hatch – compatible with all bituminous mass manufacturers

- Automatic heating system with independent bituminous mass and emulsion temperature adjustment

- Oil burner with a sealed combustion chamber – the safest solution available

- Side hatch for emergency bituminous mass tank draining

- Advanced diesel engine – Perkins 3 cylinder, water cooled, 34 HP (fuel consumption 3.5 l/h)

or Briggs & Stratton gasoline engine, 2 cylinder, air cooled, 23 HP - Extremely effective bituminous mass tank insulation – possibility of transportation of hot bituminous mass for over a dozen hours

COMPATIBLE CARRIERS

- Truck chassis – frame (intermediate frame)

- Trucks – (mounting on truck body)

- Tandem trailers 2-axle

- Tractor trailers, 2-axle

Possible additional equipment:

Bitumen sprayer with pump and hand lance

Air compressor with pneumatic instalation

Hydraulic hammer Atlas Copco, with hoses

Hydraulic asphalt cutter with diamond blade ø 300 ÷ 400 mm

2-axle towed chassis

Hydraulic diamond drill for sampling of asphalt/concrete

Support legs to remove the container from the carrier (without a jack) and storage during the seasonal break

It is possible to order thermoses with capacities other than those shown in the table below.

|

Type: |

TR-3H |

TR-4H |

TR-6H |

||

|

Capacity: |

3,0 m3 | 4,5 m3 | 6,0 m3 | ||

|

Screw feeder drive: |

hydraulic with overload protection | hydraulic with overload protection | hydraulic with overload protection | ||

|

Screw feeder rpm: |

right / left | right / left | right / left | ||

|

Top hatch: |

1170 mm x 1580 mm hydraulically opened | 1170 mm x 1580 mm hydraulically opened | 1170 mm x 1580 mm hydraulically opened | ||

|

Heating: |

Maintenance-free oil burner with digital automatic controller |

Maintenance-free oil burner with digital automatic controller | Maintenance-free oil burner with digital automatic controller | ||

|

Heating oil consumption: |

1 ÷ 3 l/h | 1 ÷ 3 l/h | 1 ÷ 3 l/h | ||

|

Insulation thickness: |

100 mm | 100 mm | 100 mm | ||

|

Hydraulic power unit: |

Yes | Yes | Yes | ||

|

Combustion engine: |

Diesel Perkins 34 HP 3-cylinder, liquid cooled Petrol Briggs & Stratton Vanguard 23 HP, 2-cylinder, air-cooled |

Diesel Perkins 34 HP 3-cylinder, liquid cooled BPetrol Briggs & Stratton Vanguard 23 HP, 2-cylinder, air-cooled |

Diesel Perkins 34 HP 3-cylinder, liquid cooled Petrol Briggs & Stratton Vanguard 23 HP, 2-cylinder, air-cooled |

||

|

Hydraulic outlet for eg. hammer drive, etc. |

Yes | Yes | Yes | ||

|

Working lights + flash: |

Yes | Yes | Yes | ||

|

Bitumen emulsion sprayer with hand lance: |

Option | Option | Option | ||

|

Air compressor: |

Option | Option | Option | ||

|

Dimensions (L x W x H) |

3500 x 2200 x 1954 mm | 4135 x 2200 x 1954 mm | 4830 x 2200 x 1954 mm | ||

|

Kerb weight: |

2140 kg | 2700 kg | 3350 kg | ||